Günther Maschinenbau

Food quality and presentation are essential for consumers. Günther Maschinenbau recognizes this need and offers innovative solutions. Since its foundation, the company has focused on high-quality machines for food businesses of all sizes.

Its expertise covers many food processes. The focus is on curing, injecting, massaging and coating. The aim of every machine is to optimize shelf life, taste and appearance.

In a demanding consumer world, food producers need reliable technology. Günther Maschinenbau responds based on decades of experience and research. The main goal: outstanding product quality for the market and enthusiasm for the end consumer.

Injectors

Injection Into Meat, Poultry, Fish and Cheese

Günther Maschinenbau is more than just technology; it is the combination of art and science for your taste experience. With our curing injectors, you not only refine taste, but also quality. Over 40 years of experience and research go into every machine.

Make your product stand out with injecting:

✓ Intensify aromas and flavors for a rich experience.

✓ Uniform coloring and texture through injected salts.

✓ Consistent reddening extends shelf life and freshness.

✓ Customers will love the reliable product consistency.

✓ Less waste and higher yield during slicing.

✓ Juiciness, taste and consistency in perfection.

✓ Increase productivity and profits.

The Technology

Injectors combine state-of-the-art technology with customizable functions for businesses of all sizes.

From craft businesses to large-scale industry: Günther has the right model for you. With the latest technology, we guarantee optimum results.

Our main features:

- Variable stitch: From 1-fold to 3-fold, for perfect brine distribution.

- Easy handling: Quick-change needle-bridge system for easy needle changes.

- Safety: Pneumatic single needle suspension protects your products.

- Efficiency: Double-head design for high production capacities.

- Thermal protection: Insulated brine circuits protect electrical/mechanical parts and minimize heat input.

Quality: Stainless steel centrifugal pumps for reliable performance; also for higher viscosities.

Tumblers, Massagers & Polter Systems

Tumblers represent German precision, innovation and top craftsmanship. In the food industry, every detail counts, and these tumblers are made for it.

When tumbling and massaging, product consistency is key. With Günther, you get even and gentle treatment for deep flavor penetration. Whether marinated meat, pickled vegetables or homogeneous mixtures - consistent top quality is guaranteed.

With Günther's energy-efficient tumblers, you are investing in technology and sustainability. Thanks to their robust design, you benefit from a long service life and reliability. This minimizes downtime and optimizes your production. Every tumbler supplied meets the highest standards. Intuitive operation and clear functions also make daily use easier.

Advantages

✓ Homogeneous consistency of end products

✓ Preservation of texture and freshness of ingredients

✓ Time saving compared to manual mixing methods

✓ Less labor and reduction of manual handling

✓ Efficient processing of large quantities in a short time

✓ Reduced risk of human error and quality problems

✓ Flexibility in processing different recipes and product types

✓ Hygienic design facilitates cleaning and minimizes cross-contamination

The specialized mixing devices from Günther Maschinenbau guarantee consistency and quality. They enable optimized production with a focus on quality and efficiency. The modern technologies in these machines ensure that you always get the best out of your ingredients. And all this with maximum conservation of resources and time savings.

Equipment Options

Tumblers from Günther Maschinenbau represent the gold standard in food processing. Based on decades of know-how and customer feedback, they offer top performance in efficiency and quality.

Their adaptability is remarkable, with solutions tailored for both boutique manufacturers and large-scale producers. With a variety of models and functions, companies can adapt their processes perfectly.

Thanks to the unique baffles, thorough yet gentle blending is ensured. This helps to maximize product quality and optimally incorporate flavours. The tilting drum is not only a testament to ergonomics and user-friendliness, but also to the efficiency gains in the work process.

The intuitive touchscreen operation simplifies adjustment and monitoring, while specialized options such as cooling and heating offer an extra dimension of precision. And with Günther's unrivaled customer service, customers can rest assured that they will receive support at every stage.

In short, for those seeking quality, efficiency and reliability, Günther Maschinenbau tumblers are the first choice. It's more than just a machine; it's an investment in excellent technology and a clear market advantage.

Coating

Coating with Sauces and Blast Freezing

Günther coating technology is an impressive example of innovation in food production. This technology allows food to be evenly and precisely coated with spices, sauces or other ingredients, ensuring consistent flavor distribution and high quality. This coating not only provides an intense taste experience, but can also help to improve the texture of the end product, for example by making pieces of meat juicier and more aromatic.

Another advantage of this technology is the subsequent shock freezing. Rapid freezing causes less damage to the cell structures of the food, which leads to better preservation of taste, texture and nutrients. Shock freezing also ensures that the applied seasonings and sauces retain their quality and that no compromises have to be made in terms of taste and consistency when defrosting and cooking the product.

For the end consumer, this means not only a high-quality product, but also easier preparation. Especially in our hectic times, ready meals or pre-prepared foods that do not compromise on quality and taste are very popular with consumers.

Good Reasons for Coating

Consistent taste

Coating ensures that every portion of your product is evenly seasoned or marinated, ensuring a consistent taste experience with every bite.

Improved texture

The combination of coating and blast freezing preserves the texture of the food and ensures that it is as fresh and juicy when defrosted and prepared as it was at the time of production.

Longer shelf life

Thanks to Günther's high-performance freezing technology, food can be stored for a longer period of time without compromising its quality. This offers consumers flexibility and variety in meal planning.

Environmentally friendly

Reducing food waste is not only good for your wallet, but also for the environment. Less wasted food means less resource consumption and less landfill waste.

Greater efficiency in production

Coating technology makes it possible to coat and blast freeze a large quantity of products in a short space of time. This means higher production rates and cost efficiency for manufacturers.

Overall, Günther Maschinenbau's coating technology represents a revolution in food processing. It combines the advantages of blast freezing with the benefits of coating and thus offers a comprehensive solution to the challenges of modern food production.

Periphery

Through continuous research and development, Günther Maschinenbau has created machines and systems that meet the latest requirements of food production. Our mixing tanks and brine preparation systems are designed to provide you with maximum efficiency, accuracy and reliability at every step of the process. This means you can be sure that your products always meet the highest quality standards and that your production runs smoothly and effectively.

The benefits:

✓ Continuous monitoring and adjustment of temperature and pH value for optimum brine quality

✓ Integration into existing production lines thanks to modular design

✓ Flexible capacities depending on company size and production requirements

✓ Touchscreen control for easy operation and setting of recipes

✓ Traceability and documentation of all processes to ensure compliance with quality standards

✓ High-quality stainless steel components ensure durability and easy maintenance

✓ Use of state-of-the-art sensor technology to monitor processes and ensure product quality

✓ Possibility of integrating additional modules for specific requirements or future expansions

✓ Reduction of manual work processes and error risks

✓ Environmentally friendly thanks to energy efficiency and low water consumption

Presses, Roller and Knife Shakers

The steaker: An indispensable tool in modern food processing.

The quality of a good piece of meat can be further enhanced. The key to this is the use of a steaker. Through targeted cuts and processing, the meat not only becomes more tender and flavorful, but also significantly improves processing and finishing.

Especially with ham products, optimal brine distribution can mean the difference between an average and an outstanding product. Brine pockets, which often form in meat, can be avoided by using a steaker. The end result? An evenly seasoned and tender piece of meat that will delight consumers.

The increased surface area created by the steaker is crucial for improved protein breakdown. This leads to better binding and ultimately a product with outstanding consistency. The ability to cut through tendons also guarantees a more pleasant mouthfeel.

The improved cut appearance and consistency of the product contribute to its exceptionally easy handling during slicing and packaging. Additionally, the optimal forming behavior achieved through the use of a press ensures consistent product quality and shape, which is particularly crucial in industrial production.

So, if you're looking for ways to improve the quality and consistency of your meat products, a steaker from Günther Maschinenbau is exactly what you need. It opens up possibilities that go far beyond conventional slicing and preparation. It's time to take your meat products to the next level.

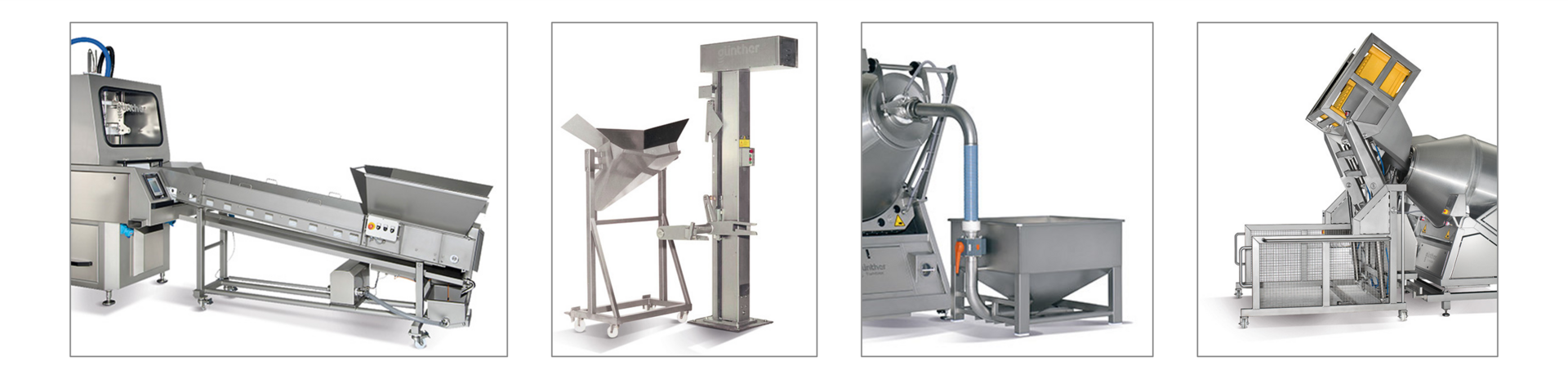

Automated Solutions for Your Line Operations

Günther Maschinenbau expands your production system. In addition to main machines, we offer peripheral solutions. Our conveyor belts transport materials efficiently and safely. Vacuum devices move products hygienically. Lifting and tilting devices manage large product volumes. Every machine increases overall performance. Flexibility and customization are our focus. Resources are saved, production times are shortened. Quality and durability are our promise. Invest in long-term optimization!